As devices end up being increasingly complicated and portable, the demand for high-grade PCB assembly producers has surged. When reviewing PCB assembly, it is crucial to comprehend not only the processes included however likewise just how to pick the best PCB assembly manufacturer to make certain that the last item fulfills the highest possible criteria of top quality and integrity.

The PCB assembly process is composed of a number of key actions, including design, assembly, and prototyping. Creating a PCB involves developing a schematic diagram that lays out how the numerous components will certainly attach with each other.

One crucial facet of PCB assembly is surface area install technology (SMT), a method that has actually changed the production process by allowing for the placing of parts directly onto the surface of the PCB. An additional typical method is through-hole modern technology, where elements are inserted right into holes on the PCB and soldered in area.

When choosing a PCB assembly manufacturer, numerous factors should be considered to make sure the best possible result. A reliable manufacturer must have a proven track document of supplying high-quality products and superb consumer service.

One more vital element to assess is the manufacturer's abilities and technology. The best PCB assembly suppliers remain at the leading edge of innovation, providing sophisticated manufacturing procedures and devices. The most up to date machinery can significantly boost the accuracy and speed of PCB assembly, ultimately guaranteeing a better output. The capability to take care of both high-volume and low-volume manufacturing runs is additionally a useful quality, as it offers adaptability based on your specific requirements. Manufacturers that invest in study and development are a lot more most likely to adopt ingenious techniques that could benefit your job.

Cost is an additional crucial consideration when picking a PCB assembly manufacturer. It is smart to obtain quotes from several producers and contrast not just the pricing yet also what is consisted of in each quote.

Lead time is additionally an essential element to consider. In today's hectic market, the ability to provide quickly can supply a significant affordable benefit. It is vital to talk about timelines ahead of time and have a clear understanding of the manufacturer's capacity to satisfy target dates. Delays in assembly can have cascading results on item launches and supply chain management, which can eventually influence a company's success.

When a suitable PCB assembly manufacturer has actually been chosen, the collaboration needs to start with open communication. Suppliers that are ready to work very closely with clients to resolve concerns or make enhancements show a reputable partnership.

Quality control steps must be in location from the early stages of assembly, including evaluations, testing, and verification processes. Utilizing automated optical evaluation (AOI) can help catch defects that may not be noticeable to the nude eye, while practical testing can verify that the put together PCB carries out correctly in real-world conditions.

As technology advancements, the landscape of PCB assembly manufacturing is changing. Fads such as miniaturization, boosted complexity, and the need for modification are driving technologies in PCB style and assembly processes. Technologies like 3D printing and laser straight imaging, together with materials that permit for adaptable and rigid-flex circuits, are examples of just how producers are adjusting to these patterns. Staying upgraded on these advancements allows a firm to choose a PCB assembly manufacturer that does not just fulfill existing needs yet is also gotten ready for future demands.

Sustainability is ending up being a significantly essential element of electronic devices making. As services and customers alike come to be extra environmentally conscious, collaborating with a PCB assembly manufacturer that prioritizes environment-friendly procedures can boost your brand name's reputation. This can include the use of lead-free solder, recycling programs, and responsible waste management practices.

When going over PCB assembly is the capacity for continuous assistance and service after the assembly is complete, an additional essential factor to consider. A top quality manufacturer does not merely deliver the set up PCB and leave; they need to be available for support with any type of concerns that might arise post-delivery. Whether it's fixing, repair services, or upgrades, having actually a trusted partner that can give ongoing support can be vital in keeping the longevity and performance of electronic products.

Looking in advance, accepting technical innovations and cultivating solid partnerships with PCB assembly manufacturers will certainly be crucial to prospering in the fast-evolving electronics landscape. As market demands continue to move, business that prioritize high-grade assembly processes, innovation, and a strong partnership with their suppliers will stand out. The merging of arising innovations, customer expectations, keep best pcba and sustainability will certainly specify the future of PCB assembly. For that reason, it is essential that companies continue to be receptive and agile to these modifications, guaranteeing they can adjust their approaches to make use of brand-new possibilities.

In final thought, navigating the globe of PCB assembly needs an extensive understanding of the manufacturing procedure, a calculated method to choosing the best PCB assembly manufacturer, and a dedication to high quality and development. Hence, selecting to work with a reputable PCB assembly manufacturer is not simply a technical choice; it is a strategic organization choice that can thrust a brand in the direction of long-term success.

Neve Campbell Then & Now!

Neve Campbell Then & Now! Lark Voorhies Then & Now!

Lark Voorhies Then & Now! Katie Holmes Then & Now!

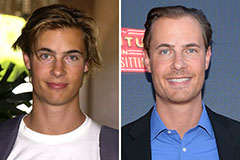

Katie Holmes Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now!